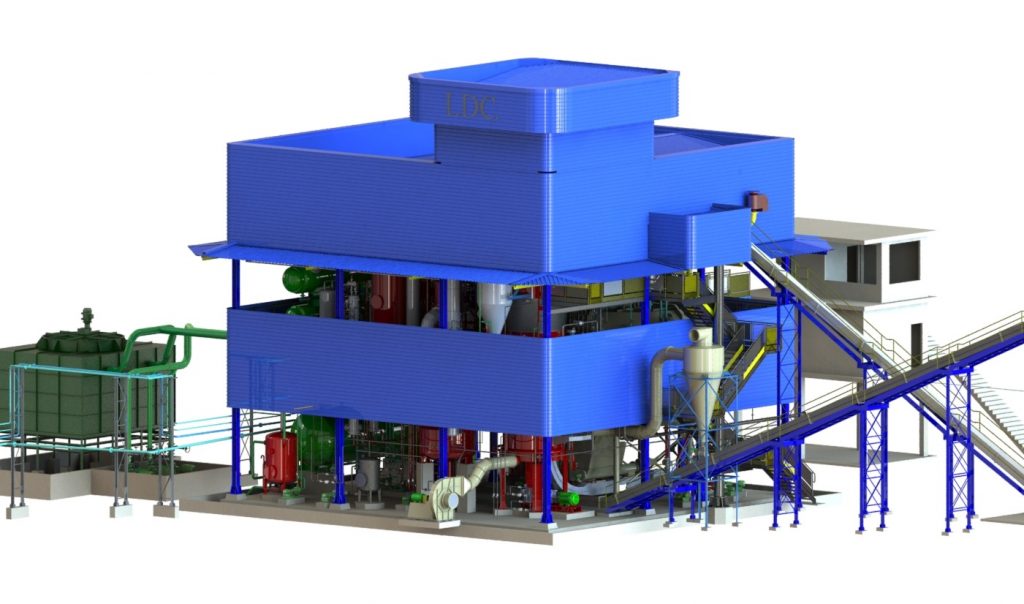

The Alliance company offers from extractors, degumming machines, oil and lecithin dryers, cookers, solvent recoverers, desolventizer-toasters, ejectors, zero effluent, hydrocyclones, gas scrubbers, decantation mats, cake breakers and oil dryers for plants of vegetable oil extraction.

There are two methods of extracting vegetable oil: mechanical or solvent pressing. It is known that the first is used in oilseeds that have a high oil content, such as cotton and sunflower. The oil is removed prior to solvent extraction and results in a partially degreased cake. It is recommended for extractions up to 300 t/d. The solvent method, in turn, has a higher oil yield and a defatted cake that is excellent for animal nutrition as the solvent prevents the rancidity of the cake. For the use of oil, the first process allows post-press consumption, while the solvent requires refinement for consumption purposes.

To obtain quality oil and cake, both methods depend on the thickness of the flakes derived from the lamination process, the adequate moisture of the dough and the temperature closest to the boiling point of the solvent. Ensure the efficiency of your plant with the entire Alliance line.

To know our equipment click here .

To know our equipment for preparation click here .